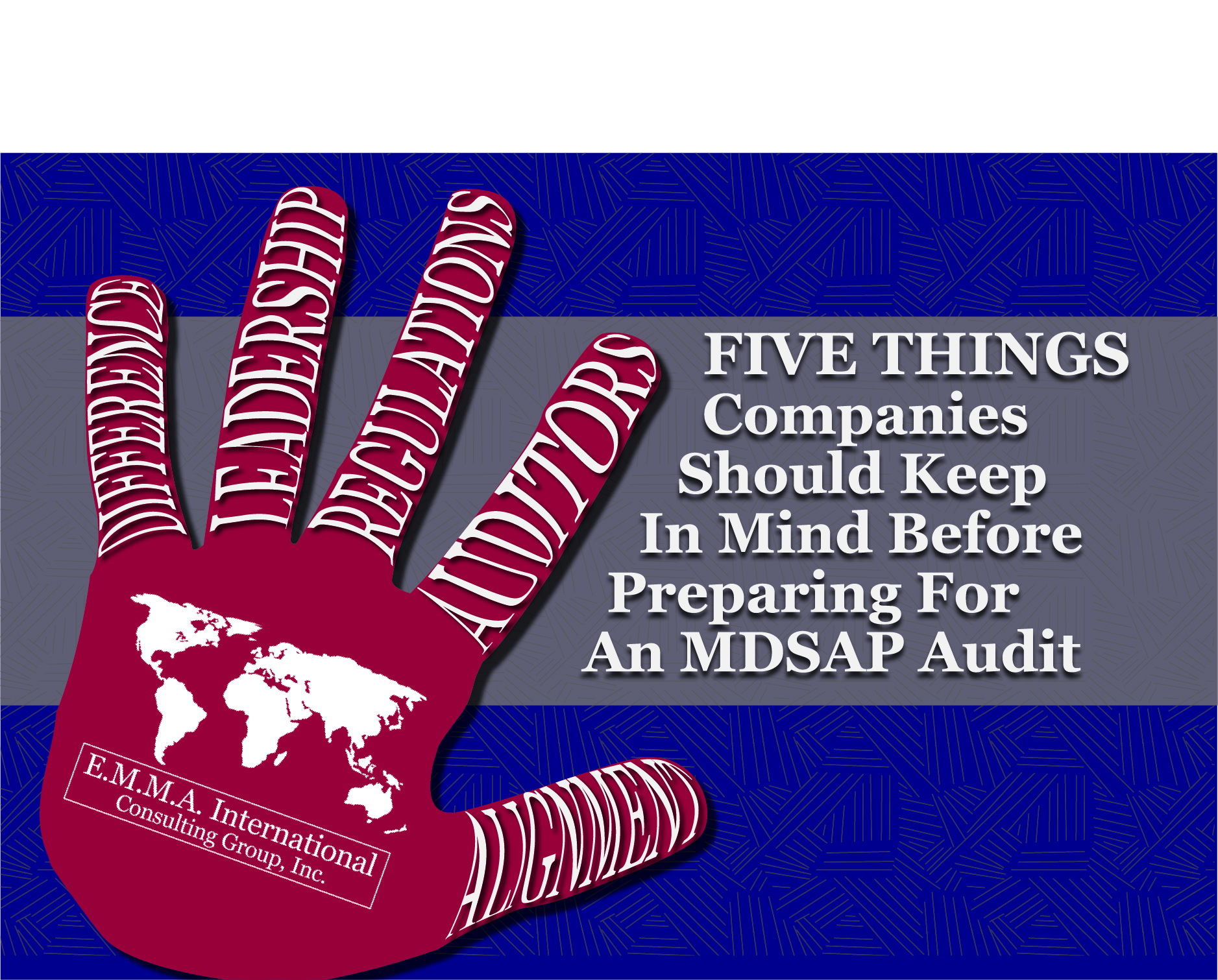

We all know how being MDSAP certified opens doors to market a device in the USA, Canada, Japan, Brazil, and Australia. Health Canada now requires medical device manufacturers to be MDSAP certified prior to January 1st ,2019 to be able to legally market medical devices in Canada. So, if you are a company that sells medical devices in Canada, you should have already made arrangements to undergo the MDSAP audit by now since the transition period is coming to an end on December 31st, 2018. If you haven’t done so and wish to get certified, our MDSAP expert Ms. Helen Gerhard shares 5 points to keep in mind to prepare yourself for the MDSAP audit.

1 The major difference between the traditional audit grading approach and the MDSAP approach is the scoring system. The quality affecting elements of the organization are scored in levels one through five in contrast to ‘major or minor findings’ and ‘opportunity for improvement’ etc. The non-conformities are graded on their potential to affect the safety and effectiveness of the medical device. If a company receives a score of four or five, which is considered severe nonconformance, the MDSAP auditors need to report it to the regulatory agency. This, in turn, might trigger an audit from the regulatory agency and further regulatory actions from the concerned authorities.

2 The MDSAP audits have a huge emphasis on the leadership element of the quality system. The MDSAP audits start and end with the evaluation of the health of the leadership system of the company. The idea is first to understand who owns and leads the processes and what they do and how they do that to preserve quality in each process.

3 Companies should remember that the baseline for the MDSAP is maintaining compliance with ISO 13485, but also with the specific applicable regulations of each country they plan to market their devices in. MDSAP provides tools for the company to determine which set of additional requirements they must follow to meet the country-specific regulations. For example- if you would like to market your device in the USA and Australia, your company needs to comply with the quality system requirements of ISO 13485 along with the specific requirements of the US-FDA’s 21 CFR 820 [QSR] and Australia’s TGA [Therapeutic Goods Administration].

4 Not every registrar or auditor is set up to do an MDSAP audit. Many auditors currently can audit for ISO 13485 but that alone will not help you achieve compliance with MDSAP. Currently, only 3 auditing organizations are recognized by all of the five participating countries.

5 The last thing to keep in mind is that this is just the beginning of the alignment of multiple regulatory forces. A lot of countries will get on board; actually, some of them are currently scaling their resources to adopt MDSAP. This clearly means a bigger and a growing market for your medical device.

To know more about the MDSAP or if you need help in getting your company MDSAP ready, please call us at (248) 987-4497 or email at info@emmainternational.com.