The rapid expansion of computing is attributed to the consistent improvement in capabilities, speed, and performance from the collective efforts of electrical and computer science engineers. Nearly every two years, these developers tend to double the number of components in an integrated computer chip, first observed by Gordon Moore in 19751. This has since been the basis of Moore’s law, which centers around the number of transistors a microchip can contain. However, there are obvious physical limitations to this law so there have been recently developed alternative approaches that have a promising outlook for extending, or at the very least complementing Moore’s law1.

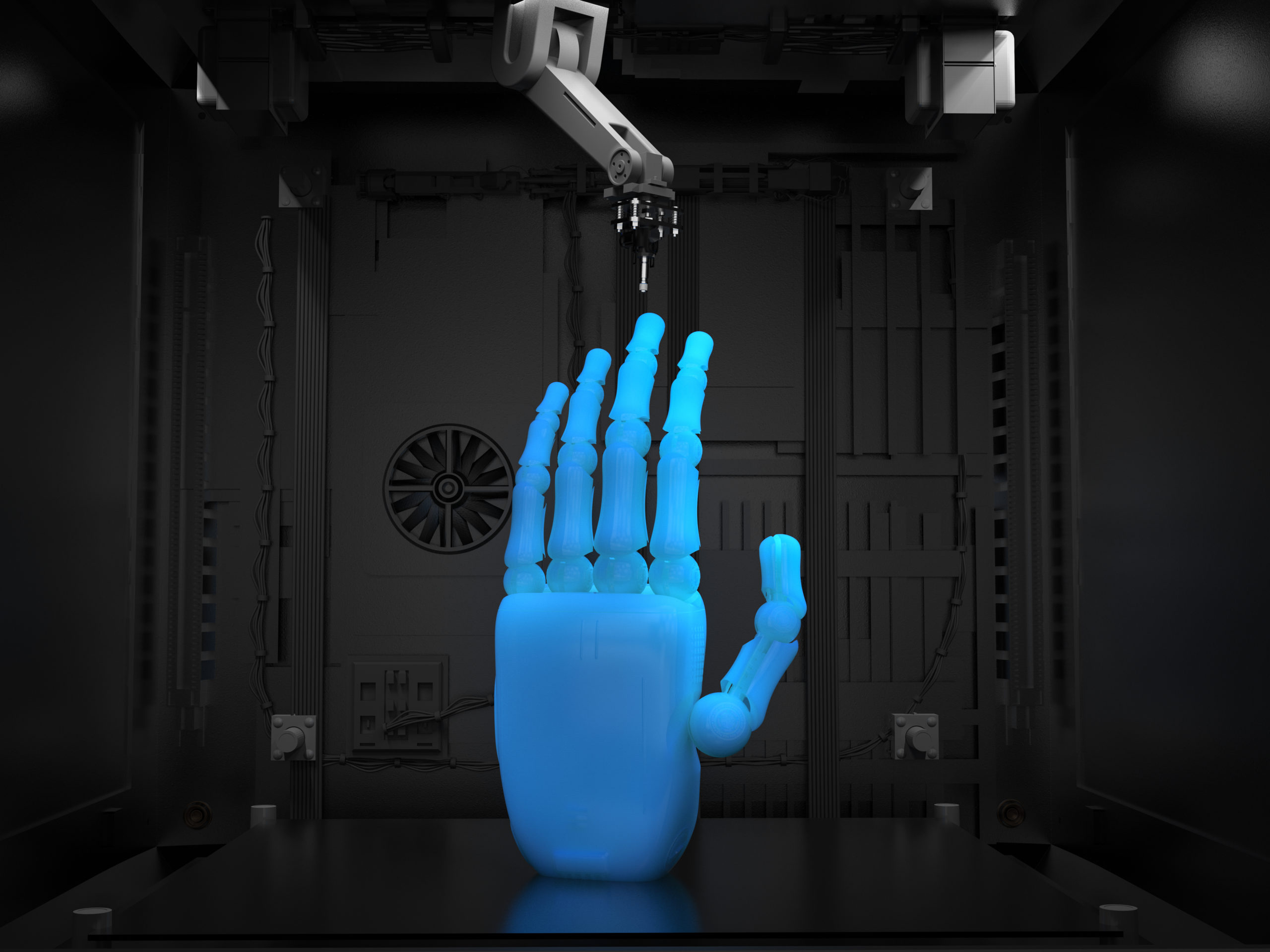

Since the inception of the 3D printer, the possible applications have been far and wide with buzzing optimism. One application pertaining to Moore’s law is 3D printing complex functional circuits and electrical driven devices using Additively Manufactured Electronic (AME) Technology and Systems. This form of 3D printing is labeled as 3D heterogeneous integration. The underlying feature of this method allows engineers to define every voxel (3D pixel) as either a conductor or isolator. Potential uses of this technology can be foreseen in approaches such as molecular transistors, and quantum, biological, protein, and DNA computers. The versatility is unique because of the various disciplines 3D heterogeneous integration can work into a single product, such as electrical, optical, thermal, magnetic, or mechanical properties1.

Quality and regulatory play a pivotal role in introducing state-of-the-art technology into the medical industry such as the 3D heterogeneous integration. While advantages are inherently present, there must be adequately developed processes and procedures in place to mitigate liabilities and overall risk. These processes and procedures are not easy to establish and implement, but QA/RA experts will provide a thorough methodology that will walk through every facet of newly introduced technology. At EMMA International, the team uses a multitude of current published standards to help those with all QA/RA needs for a diverse range of medical technology, pharmaceuticals, and biologics. With the rapid innovation of computing year after year affecting practically every industry, especially healthcare, quality and regulatory must be enforced to avoid design assumptions with catastrophic capabilities.

EMMA International is here to provide full-circle solutions for all sectors of the MedTech industry. Give us a call at 248-987-4497 or email us at info@emmainternational.com to learn more about how EMMA International can help with quality and regulatory compliance today!

[1] Nanodimension (2021) How 3D integrated components can take us beyond Moore’s Law, Retrieved on 20 July 2021 from: https://www.nanodi.com/hubfs/2021_Marketing_Assets/Moore_Law_Nano_Dimension.pdf?li_fat_id=c5de632d-9d8f-4ec1-93a6-b5b2dadef17f