The field of biomedical engineering is a new, widely researched, and well-funded industry that aims to tackle problems in medicine and health by providing engineered solutions. These solutions might be delivered in the form of electrical hardware, chemicals, or even software. Given the extensive range of applications that exist in the medical device industry, the field is continuously accelerating its innovations in technology via an abundance of research and innovation outlets in countless interrelated fields. One of the many fields that are fundamentally fueling the growth of the biomedical industry is material science.

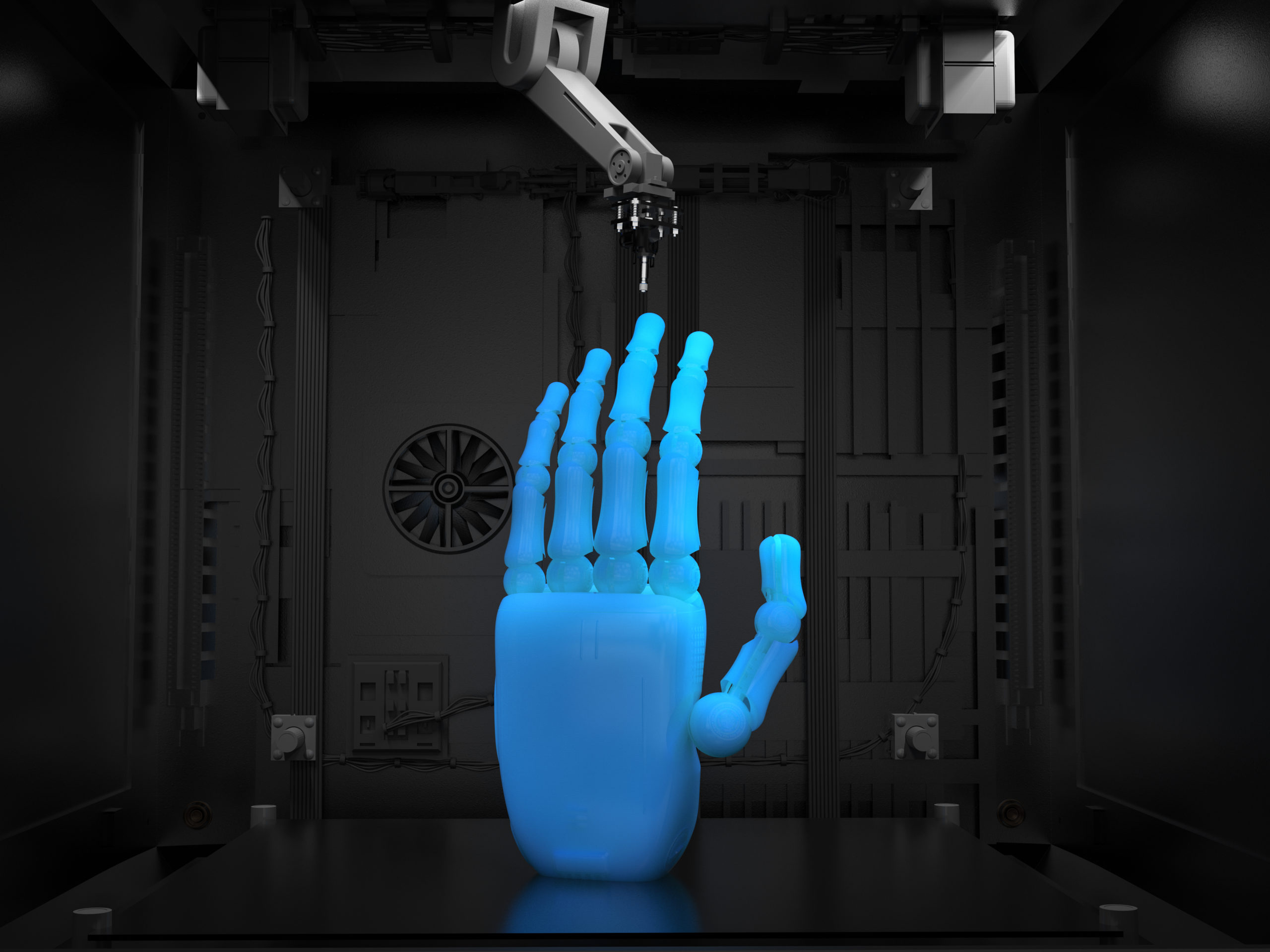

Material science aims to deliver new and improved materials by understanding their structure, from the atomic scale to the micro and macro scale. By altering the structure of materials via chemical, mechanical, electrical, or thermal processes, the functions of materials can be uniquely specified to fit a precise application. Some of the many new trends in materials science and engineering that have led to new products and devices in the medical industry include 3D printing of custom-fit prosthetics and scaffolds, nanomaterials for drug delivery systems, or composites such as Ag-doped Bioactive glass for orthopedic repair while maintaining bacterial resistance.1,2 For example, 3D printing technologies have allowed for uniquely individualized prosthetic limbs to be made out of polymers, metal alloys, or even ceramic composites with unique specificity to the implantee via computed tomography. Material science has long been a foundation of industry in continuously developing or altering new materials to adapt to the needs of improving technologies,

As material science continues to deliver functionally new materials and technologies across the life sciences and biotech industries, regulations will continuously be implemented to ensure their safety, quality, and effectiveness. If you need help with any quality, regulatory, or compliance aspect of your product, EMMA International’s team of experts has you covered. Contact us at 248-987-4497, or email info@emmainternational.com today!

1 Patra, J.K., Das, G., Fraceto, (19 September 2018), Nano Based Drug Delivery Systems: Recent Developments and Future Prospects. Journal of Nanobiotech. https://jnanobiotechnology.biomedcentral.com/articles/10.1186/s12951-018-0392-8#citeas

2 Pajares-Chamorro, N., & Chatzistavrou. X., (2020). Bioctive Glass Nanoparticles for Tissue Regeneration. ACS Omega. https://www.egr.msu.edu/biomaterials/projects