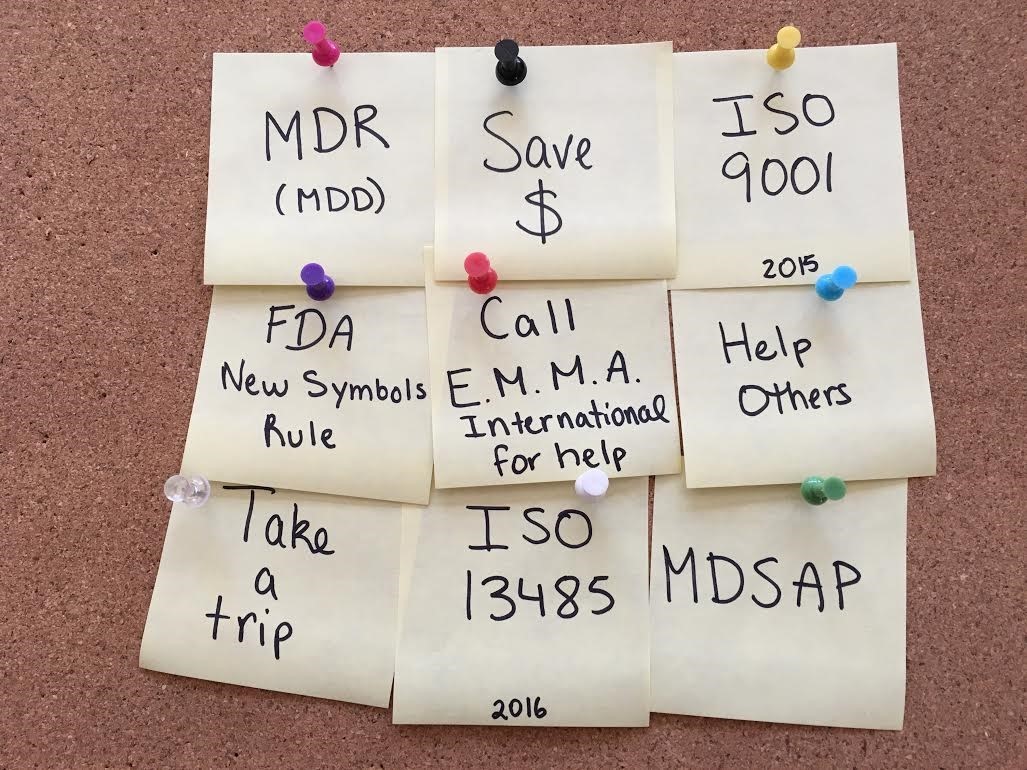

First, EMMA International would like to wish everyone a wonderful and prosperous new year. However, we know that a new year can also bring new challenges. In 2017, you can:

- Transition from ISO 9001:2008 to ISO 9001:2015

- Transition from ISO 13485:2003 to ISO 13485:2016

- Get up to speed with the Medical Device Single Audit Program (MDSAP)

Don’t worry! Now is the time to start the transition and EMMA International can help every step of the way. But it is important to start now. The industry is anticipating long wait times with certified bodies, so it is important to get your renewals on the schedule now.

So, don’t stress. Let EMMA International conduct a gap analysis, help remediate the gaps, provide staff development and training and be your support throughout this process. Set your New Year’s Quality and Regulatory Resolutions with EMMA International and enjoy working with a strategic partner who will support you every step of the way!

For more information, please contact:

Janet Bloom, VP of Business Development

248-445-1033 or janet.bloom@emmainternational.com