Evolution is the process of how a species changes over time in response to their environment. Often termed “Survival of the Fittest”, the topic was studied most famously by Charles Darwin. While it is present across all species, one of the biggest impacts it can make is the change in a microorganism’s genome to resist antimicrobial products. These are used to treat and cure infections and sterilize surfaces among others. For this reason, antimicrobial resistance (AMR) has become a global concern. According to the Centers for Disease Control and Prevention (CDC) in the US, each year at least 2.8 million AMR infections resulting in 35,000 deaths (United States Food and Drug Administration, 2022) (World Health Organization, 2021).

The United States Food and Drug Administration (FDA) and World Health Organization (WHO) have placed special emphases on fighting AMR since it is such an important topic. Because of this, the FDA assembled a task force to detect, prevent, and limit the impact of AMR. This involves facilitating the development of equipment to detect AMR and minimize it, improving current approaches, and help development of new drugs and cleaning products to fight this.

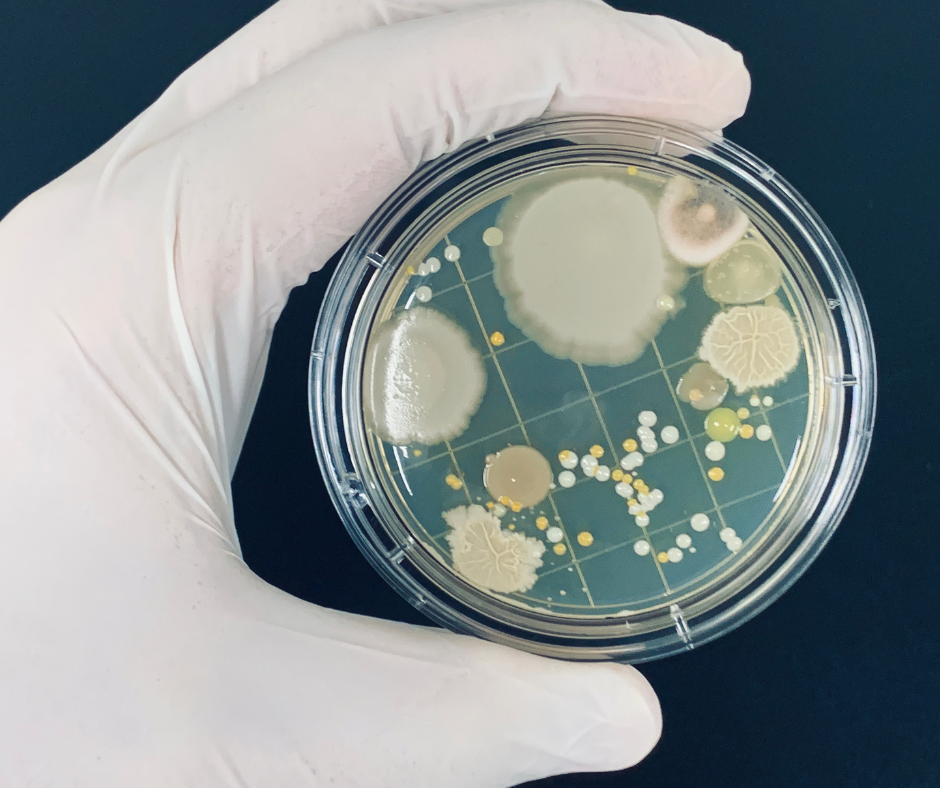

Microbial activity in a production environment is also problematic as it can affect product quality. Therefore, effective cleaning procedures must be put into place in order to minimize this. A very common practice in the workplace is to rotate cleaning agents to prevent this and the microbe’s ability to develop a resistance to the cleaning agents. Cleaning in this way in key areas, such as sterility hoods and clean room environments, allows for an effective environmental monitoring program to allow for production in a controlled environment.

If you need support in developing an effective cleaning program to ensure your systems are operating in a state of control to prevent AMR build-up and maintain environmental quality, the experts at EMMA International can help! Call us at 248-987-4497 or email us at info@emmainternational.com to learn more.

United States Food and Drug Administration. (2022, September 6). Focus Area: Antimicrobial Resistance.

World Health Organization. (2021, November 17). Antimicrobial Resistance.