As the digital age continues to advance at an amazing pace, healthcare and medical devices have managed to keep up with the rest of technology. These advanced technologies have allowed average people to take their health into their own hands. Everything from a heart rate monitor to smart inhalers are now available on the market for the general public to purchase.

While these products are innovative and make it convenient for people to monitor and improve their health that does not exclude them from having to follow the same regulations as any other medical device. Most devices that impact human health in any capacity for sale in the United States are regulated by the FDA, other countries have their own regulatory bodies that will often do the same. For example, the FDA regulates treadmills and other physical medical devices under Title 21 CFR part 890.[1] Digital devices and the software that may accompany them are also regulated under the FDA.

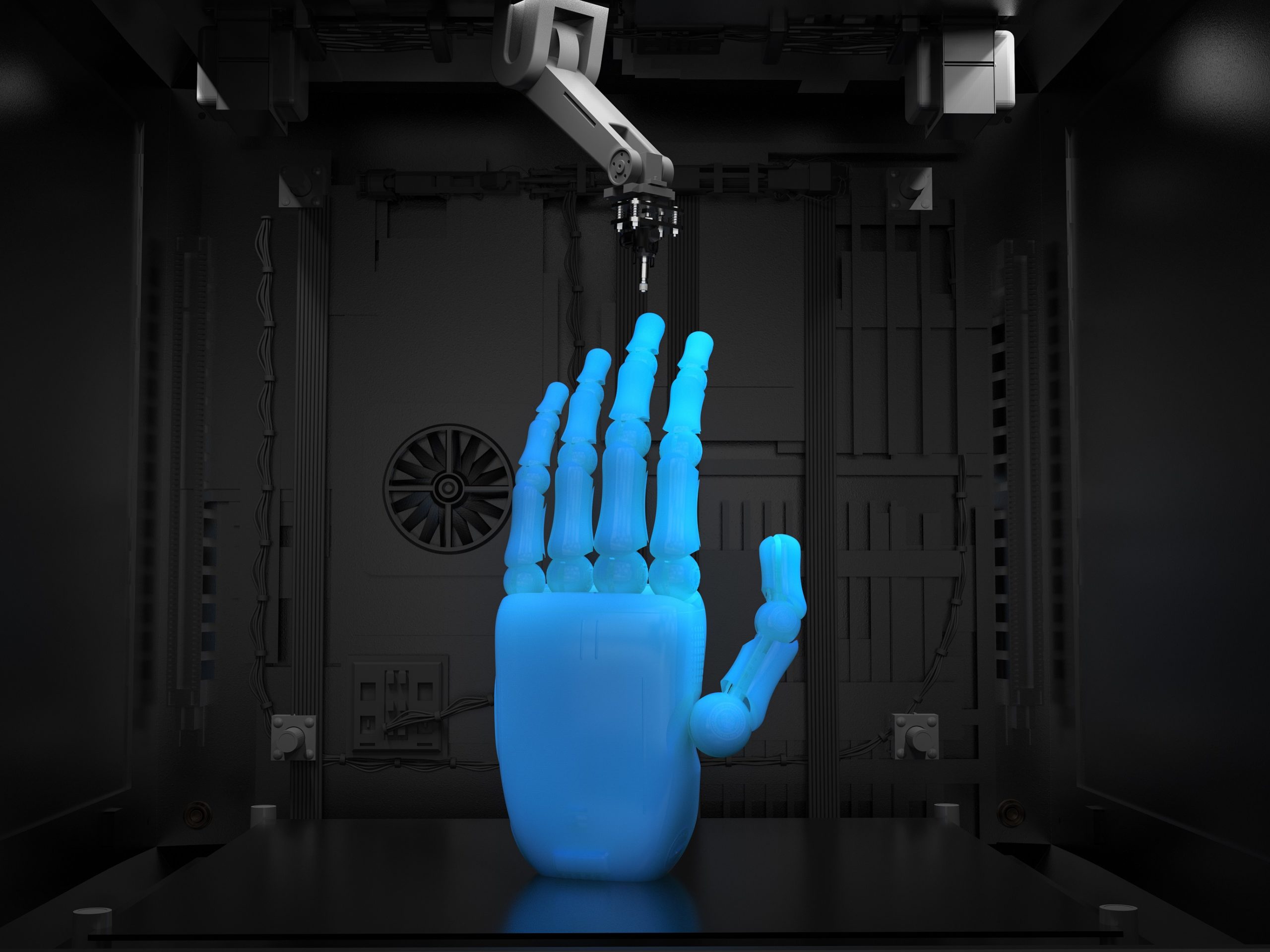

These consumer products are not the end of the new age of medical devices. Amazing devices are being developed every day with the combined efforts of engineers, healthcare professionals, chemists, and more. Nanotechnology is currently an avenue that many companies are pursuing to further innovate healthcare. While it may sound more like science fiction than real life, nanotechnology may soon be a very real medical device that is used in the treatment of all kinds of conditions. The possibility of nanotechnology medical devices is so real that the FDA has outlined its approach on how it would go about regulating such devices if the need was to ever arise.[2]

Companies developing these innovative products range from large multi-million-dollar corporations to small start-ups. Regardless of the size of the company these innovations can be world-changing. Meeting all the necessary requirements set by the FDA or other regulatory bodies to get a product on the market can be a challenge. It will not matter how incredible a device is if it never makes it to the customers. EMMA International can help bring products onto the market. From ensuring that all the necessary quality systems and procedures are in place to helping file the needed registration paperwork, EMMA International does it all. EMMA International can help innovation reach reality, give us a call at 248-987-4497 or email info@emmainternational.com to get in touch with our team of experts today.

[1] FDA (April 2020) Part 890 – Physical Medical Devices, Retrieved 10/30/2021 from https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=890.5380

[2] FDA (March 2018) FDA’s Approach to Regulation of Nanotechnology Products, Retrieved 10/30/2021 from https://www.fda.gov/science-research/nanotechnology-programs-fda/fdas-approach-regulation-nanotechnology-products