Biotechnology manufacturing is a complex and highly regulated field that demands precision, consistency, and efficiency. To meet these requirements, biotech companies are increasingly turning to advanced automation and control systems. These technologies streamline processes, enhance productivity, and ensure compliance with stringent regulatory standards. Here, we explore some of the most popular automation and control systems used in biotech manufacturing.

1. Distributed Control Systems (DCS)

Distributed Control Systems (DCS) are widely used in biotech manufacturing for their ability to monitor and control multiple processes across a large facility. A DCS integrates various subsystems, such as process control, data acquisition, and reporting, into a single, cohesive system. This integration allows for real-time monitoring and control of manufacturing processes, ensuring consistent quality and efficiency. Key benefits include:

- Scalability: Easily scalable to accommodate expanding production lines.

- Reliability: High reliability and uptime due to decentralized control.

- Data Integration: Seamless integration with other enterprise systems for comprehensive data analysis.

2. Supervisory Control and Data Acquisition (SCADA)

SCADA systems are essential for real-time monitoring and control of biotech manufacturing processes. These systems collect data from sensors and equipment across the facility and provide a centralized platform for operators to monitor and manage operations. SCADA systems are crucial for:

- Real-time Data Monitoring: Continuous monitoring of critical parameters such as temperature, pressure, and pH levels.

- Alarm Management: Immediate alerts for any deviations from set parameters, enabling quick corrective actions.

- Data Logging: Comprehensive data logging for compliance reporting and process optimization.

3. Programmable Logic Controllers (PLCs)

Programmable Logic Controllers (PLCs) are versatile automation tools used extensively in biotech manufacturing. PLCs are designed to control a wide range of processes and machinery, from simple assembly lines to complex fermentation systems. They offer:

- Flexibility: Easily programmable for various applications and processes.

- Durability: Robust design suitable for harsh manufacturing environments.

- Real-time Control: Immediate response to changes in process conditions, ensuring optimal performance.

4. Manufacturing Execution Systems (MES)

Manufacturing Execution Systems (MES) bridge the gap between enterprise resource planning (ERP) systems and the shop floor. MES provides real-time data on manufacturing operations, enabling better decision-making and process optimization. In biotech manufacturing, MES systems help with:

- Production Tracking: Detailed tracking of production batches and workflows.

- Quality Management: Integration with quality control systems to ensure compliance with regulatory standards.

- Process Optimization: Identification of bottlenecks and inefficiencies for continuous improvement.

5. Batch Control Systems

Batch control systems are specifically designed for processes that produce products in batches, such as biopharmaceuticals. These systems ensure that each batch meets the required specifications and regulatory standards. Key features include:

- Recipe Management: Precise control of recipes and formulations for each batch.

- Traceability: Detailed tracking of batch history and genealogy for regulatory compliance.

- Consistency: Ensuring uniformity across all batches, reducing variability and enhancing product quality.

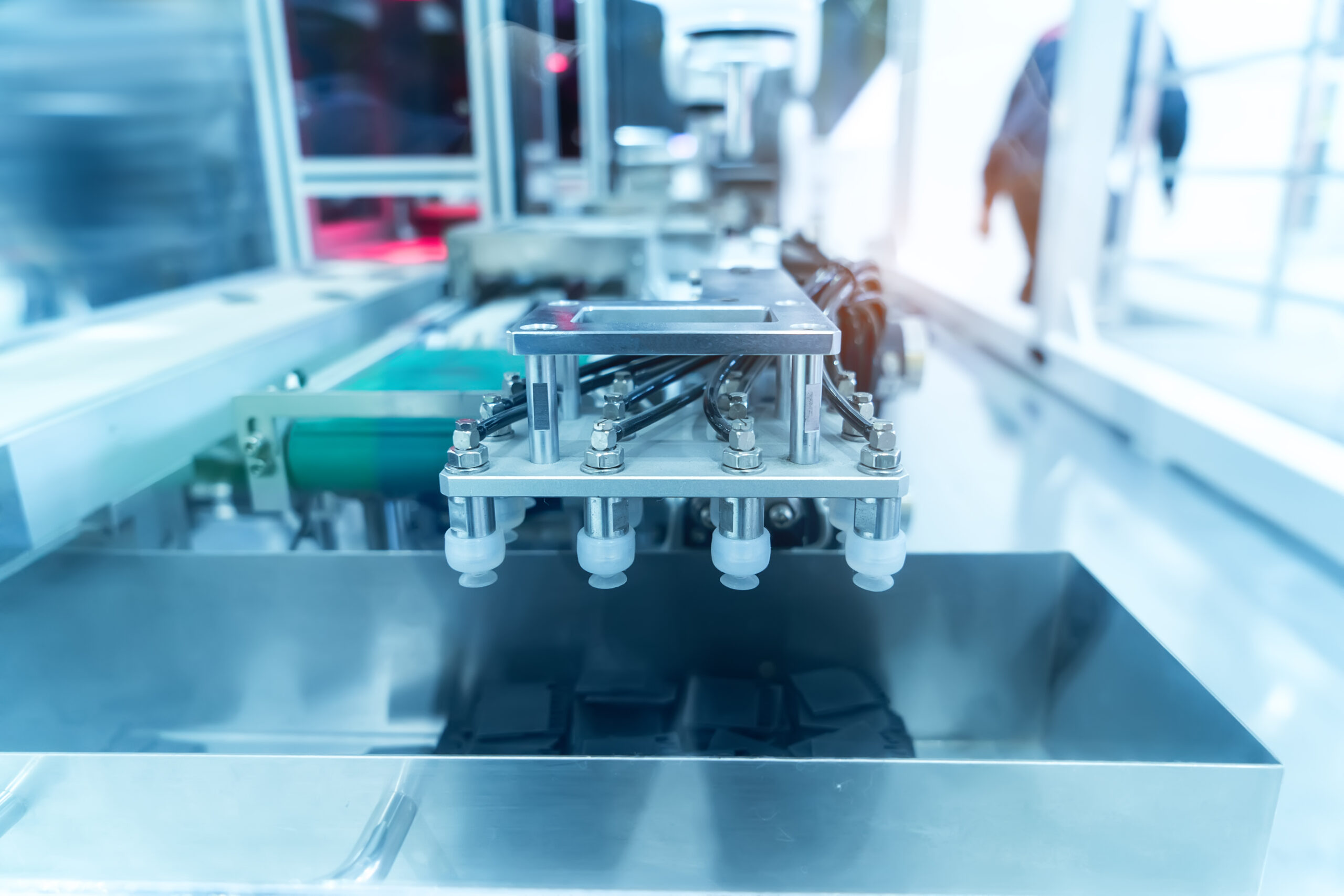

6. Robotic Process Automation (RPA)

Robotic Process Automation (RPA) is becoming increasingly popular in biotech manufacturing for automating repetitive and time-consuming tasks. RPA can handle tasks such as data entry, sample handling, and equipment maintenance, freeing up human resources for more complex activities. Benefits of RPA include:

- Efficiency: Increased operational efficiency by automating routine tasks.

- Accuracy: Reduced risk of human error in critical processes.

- Scalability: Easy to scale and adapt to changing production needs.

7. Laboratory Information Management Systems (LIMS)

Laboratory Information Management Systems (LIMS) are crucial for managing data and workflows in biotech manufacturing laboratories. LIMS streamline sample tracking, data management, and compliance reporting. They offer:

- Data Management: Centralized database for all laboratory data, ensuring accuracy and accessibility.

- Workflow Automation: Automated workflows for sample processing, testing, and reporting.

- Regulatory Compliance: Built-in compliance features for regulatory standards such as GLP and GMP.

The integration of advanced automation and control systems in biotech manufacturing is transforming the industry. These systems enhance precision, efficiency, and compliance, ensuring that biotech products meet the highest standards of quality and safety. As technology continues to evolve, biotech manufacturers will increasingly rely on these systems to stay competitive and drive innovation. By adopting these popular automation and control systems, biotech companies can optimize their operations and achieve greater success in this dynamic and challenging field.

Stay ahead of the curve with our state-of-the-art automation support solutions. We integrate advanced control systems to streamline operations, enhance data accuracy, and boost productivity. Get in touch with our team of experts by calling 248-987-4497 or by emailing info@emmainternational.com today.

FDA (Sep 2022) Computer Software Assurance for Production and Quality System Software retrieved from: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/computer-software-assurance-production-and-quality-system-software