While going through my daily tech-news, I came across an interesting piece of research relating to 3D printing. Scientists at the Tel Aviv University, Israel, 3D printed the world’s first human heart using actual human tissues.1 I knew the basic definition of 3D printing but after going through this impeccable research work, I was surprised to learn that there has been such a level of technological advancements in 3D printing and biomedical research.

3D Printing is also referred to as “additive manufacturing”, it is the process of building 3D objects using Computer-Aided Design (CAD) which is a digital image generated in a 3D space. This image defines the structure of the object and it is fed to the printer to construct 3D objects. Coming from a software engineering background, my major area of interest was to unravel how does an internal software tool process images and instruct the hardware to create such a dimensionally accurate real-world object.

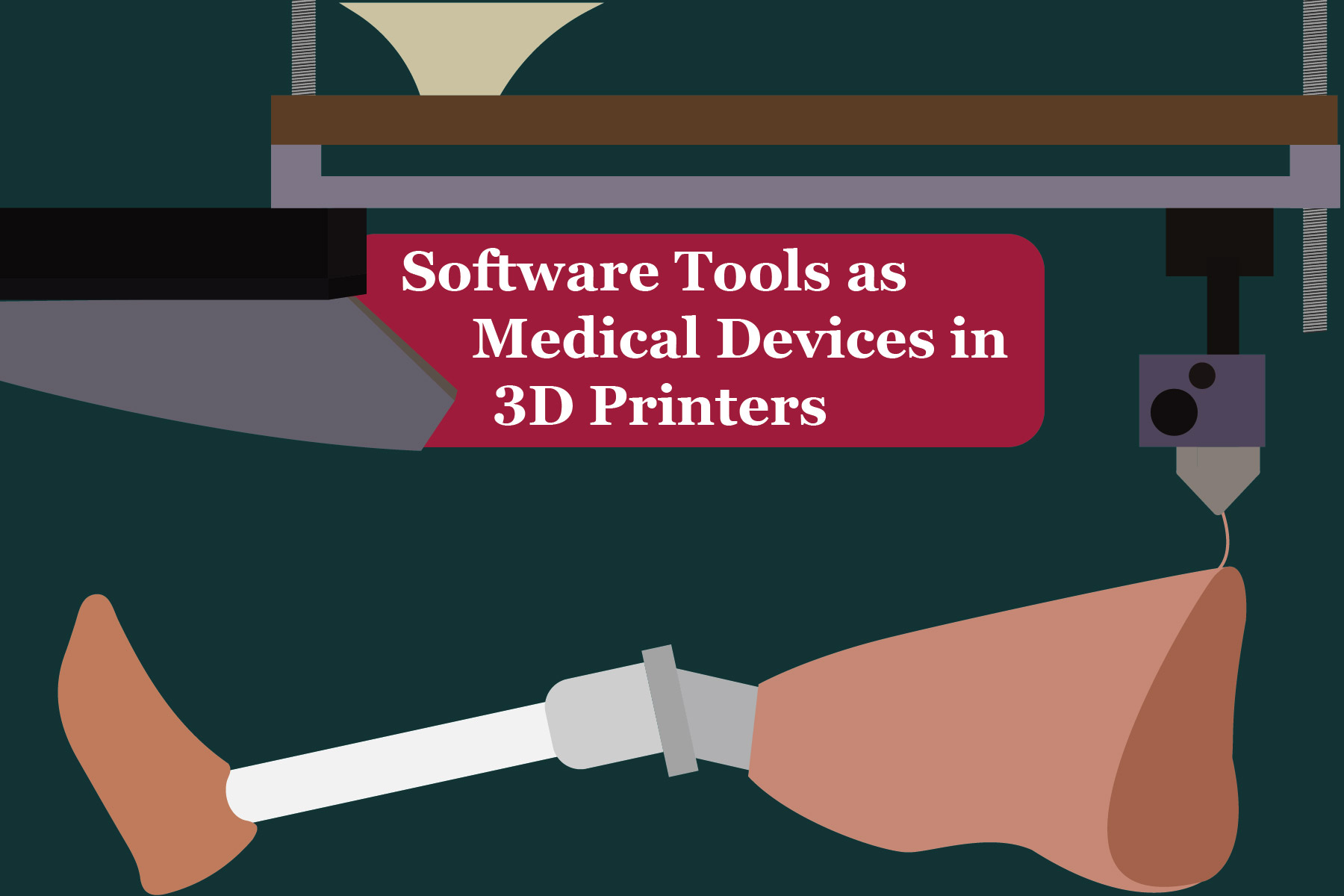

The 3D printer works like a simple inkjet printer that is operated via a machine. In the case of 3D printers, the 3D CAD model is broken down into many cross-sectional 2D models by the internal software. Based on these 2D images, the printing starts from the very bottom layer. It then keeps adding molten plastic or metal one layer after the other till the complete object is fused and completed. Indeed, software plays a key role right from the 3D object design to object monitoring (during printing) and completion.2

3D-printing is categorized based on two major design types. If a standard object is to be 3D printed, the same design could be utilized to manufacture multiple objects many times. The second type that caught my attention is the custom-made CAD design which is used for manufacturing patient-specific objects such as external prostheses (i.e. artificial limbs or hands). Following my research, I thought of a software tool where these 3D-printers are integrated with an AI/ML-based image recognition algorithm. Especially in the case of prostheses, a complete body image of a patient could be fed to an AI model that is trained on millions of patient-body images. This AI model records the dimensions of the person from the newly fed image, and based on the learned dataset, it generates the required prostheses CAD image. An additional tweak to this tool could be supplying this image to the 3D-printer directly using Cloud or wireless networks. Such an integrated and automated software tool will significantly increase manufacturing productivity and immensely facilitate precision while drafting the CAD model.3

Based on the discussed software integration approach with these 3D printers, if the software tools in these devices are considered medical devices then they must be thoroughly verified and validated. Surely, several activities are involved in software validation and it can get tricky to implement and execute these validation processes without any support. Such activities include documenting the software requirements, architecture, conducting in-depth code testing with quality inspections, and most vitally, risk-assessment of the software tool. This is where our team from EMMA International can provide you a helping hand for validating your software and hardware device. We can guide you step-by-step through the FDA compliance process and make sure your medical device follows all the required FDA regulatory guidelines. Do you have a software tool or a medical device that is utilized in additive manufacturing, and do you want it to get FDA cleared or approved? Contact us at 248-987-4497 or info@emmainternational.com for more information.

1Colin Drury (April 2019). Scientists make ‘world’s first 3D printed heart using human tissue’. Retrieved on February 5th, 2021 from https://www.independent.co.uk/news/world/middle-east/heart-3d-printed-human-tissue-tel-aviv-university-israel-a8872631.html.

2FDA (December 2017). Process of 3D Printing Medical Devices. Retrieved on February 5th, 2021 from https://www.fda.gov/medical-devices/3d-printing-medical-devices/process-3d-printing-medical-devices.

3Jawad, M. S., Bezbradica, M., Crane, M., & Alijel, M. K. (2019, October). AI Cloud-Based Smart Manufacturing and 3D Printing Techniques for Future In-House Production. In 2019 International Conference on Artificial Intelligence and Advanced Manufacturing (AIAM) (pp. 747-749). IEEE.